Why Choose Urethane Casting?

Urethane Castings are utilized by many industries in search of a cost effective solution to build small to medium volumes of parts where there may not be the budget to invest in injection mold tooling or even that quantity of 3D printed components. The cost of polyurethane parts is about 10% of the cost of a 3D printed part. The silicone tooling cost is also roughly 10% or less than the cost of a traditional injection mold and can typically be produced in 1-2 weeks. This process allows designers and engineers to receive production-like components for a fraction of the cost utilizing polyurethane materials which mimic the properties of thermoplastics.

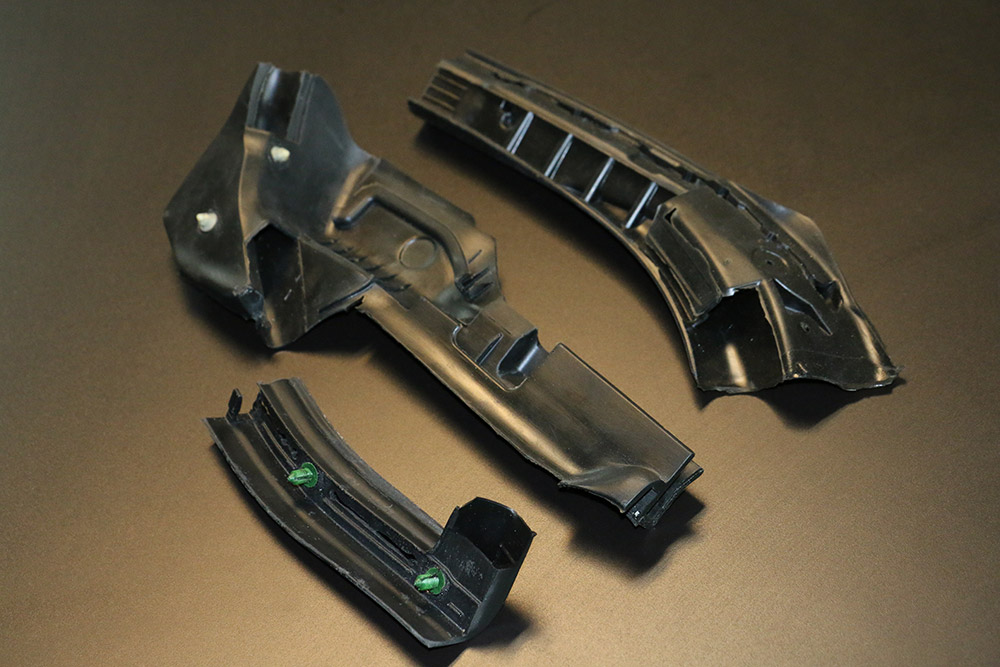

How Urethane Casting Works

In urethane casting, the master model is first produced, usually by a 3D printing method such as SLA, then the master is sanded and painted to the desired finish level and then encapsulated in silicone. The next day, the mold maker then creates a parting line and splits the mold into a cavity and core. The master model is then removed and then two-part polyurethane is injected into the mold to form the part. From one mold, you can typically expect to get at least 50 shots before the mold begins to deteriorate, at which point a new mold would need to be built in order to make more parts. There are many polyurethane materials to choose from which will assimilate ABS, Polypropylene, Polycarbonate, Nylon, and even rubber. Over-molded parts are also possible with this process, where you may require certain aspects of your part to be flexible, while others remain rigid. We can help you decide whether it’s logical to go this route or whether 3D printed parts or injection molding makes more sense for your project needs and budget.

Urethane Casting Applications:

- Aerospace or Automotive Interior Components

- Consumer Product Prototypes

- Trade Show or Exhibit Models

- Pre-production runs

- Engineering Models

- Over-molded parts

- Consumer Testing

- Sales Samples

- Low Volume Parts

- Concept Models

Whether you’re a small local business trying to grow or a multi-national OEM, we will put our best foot forward and provide you the best value and quality to ensure your needs are met. iDEAL Technology Corporation is dedicated to providing quality custom tooling, check fixtures and gages, rapid prototyping / 3D printing / urethane casting, assembly equipment, CNC machining, studio models and bucks to industries all over the world.

Download our Urethane Casting Services brochure here